Solid PVC boards are highly durable, lightweight, and water-resistant, making them ideal for furniture manufacturing and construction. Their versatility allows for use in cabinetry, wall panels, and plastic formwork. Additionally, PVC boards are easy to maintain, ensuring a long-lasting, attractive finish for both residential and commercial applications.

Specification

| Name | Pvc foam board |

| Density | 0.35~0.9g/cm |

| Color | White、Customized |

| Place of Origin | Guangzhou,China |

| Main Material | 100% PVC |

| Regular Size | 1220x2440mm (4'x8') or customization |

| Service | OEM |

| Size | 1220*2440mm,1220*1830mm,1000*2000mm,915*1915mm,Customiztion |

| After sales service | 24 Hours On-Line Support |

| Thickness | 1mm,2mm,5mm,8mm,10mm,12mm,15mm,18mm,20mm,etc. |

| Application | Advertising Signage,Outdoor Advertising,Signboard Production, |

| Payment | 30% deposit, 70% balance before shipment. |

| Packing | Carton box or wooden pallet or PE Bag package. |

Product detail

How PVC Boards Combat Fire Risks

PVC boards are ideal for window display panels and furniture due to their fire-resistant properties. They slow flame spread and emit minimal smoke, enhancing safety. Combined with EVA foam sheets, they offer added cushioning, effectively mitigating fire risks in construction and design.

The Science Behind PVC Board Water Resistance

PVC boards are known for their excellent water resistance, making them ideal for solid applications and plastic formwork for concrete. Their hydrophobic structure prevents water absorption and reduces mold risks.

Exploring the High Hardness of PVC Boards

PVC foam boards are prized for their high hardness, enhancing durability and impact resistance, making them perfect for window display panels and furniture. This property prevents warping and bending, ensuring structural integrity.

PVC Foam Boards: A Responsible Material Option

PVC foam boards are eco-friendly and recyclable, ideal for solid applications and plastic formwork. Their durability reduces replacements and conserves resources, while responsibly produced boards emit fewer harmful substances. Combined with EVA foam sheets, they enhance insulation, making them a sustainable choice for eco-conscious projects.

The Science Behind Edge Finishing in PVC Cutting

Clean, burr-free edges in PVC boards are crucial for window display panels and furniture materials. Precision cutting techniques, like CNC routing and laser cutting, minimize friction, ensuring smooth edges.

How Custom Sizes Improve PVC Board Usability

Custom sizes for PVC boards enhance usability in window display panels and furniture materials by ensuring a perfect fit and optimizing design efficiency. This approach minimizes waste, supports eco-friendly practices, and improves compatibility with other materials like EVA foam sheets, resulting in versatile and cohesive project designs.

Why choose us?

(1)Quality Materials

We use premium materials like solid PVC boards and EVA foam sheets, ensuring durability and longevity in all our products, including plastic formwork for concrete.

(2)Innovative Solutions

Our expertise in combining materials allows us to provide innovative solutions tailored to your needs, enhancing performance and functionality for various applications.

(3)Customer-Centric Approach

We prioritize your satisfaction, offering personalized support and timely delivery, ensuring that you receive the best value and service for your projects.

Raw material

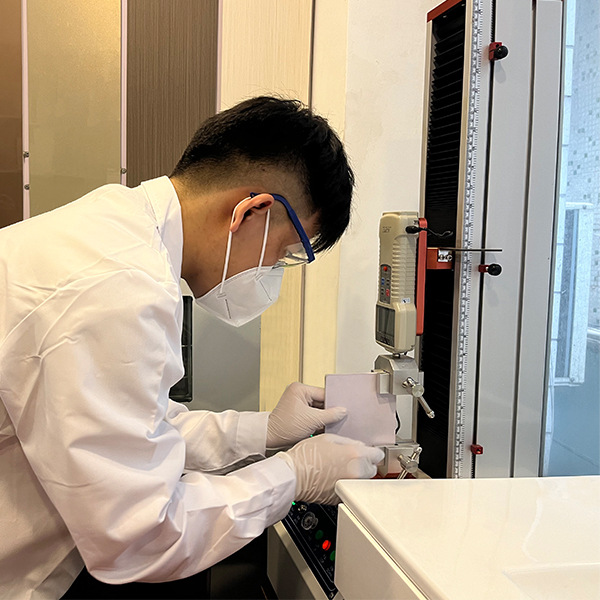

R&D Center

Production equipment

Product warehousing

Production process

(1)Extrusion Machines

Extrusion machines are essential for producing solid PVC boards and foam boards. These machines melt and shape PVC materials into sheets, ensuring uniform thickness and high-quality output for applications like plastic formwork for concrete.

(2)CNC Cutting Tools

CNC cutting tools are crucial for precision cutting of PVC boards. They allow for intricate designs and exact dimensions, making them ideal for various applications, including furniture products and window display panels.

(3)Lamination Equipment

Lamination equipment enhances the durability and aesthetic appeal of PVC boards by applying protective films or coatings. This process improves resistance to moisture and wear, making the boards suitable for demanding environments.

Cutting machine tool

Product production

Product production

Product production

Packing & Delivery

(1)Protective Packaging

Use sturdy materials like corrugated boxes or wooden crates to safeguard PVC boards during transport, ensuring they arrive intact for applications like solid PVC boards and plastic formwork.

(2)Secure Stacking

Stack PVC boards flat and securely to prevent bending or warping, maintaining their integrity for use in construction and other demanding environments.

(3)Clear Labeling

Label packages with handling instructions like “Fragile” to ensure careful treatment during transit, reducing the risk of damage.

Wooden pallet packaging

PE bag packaging

FTL

FCL

Applications

(1)Signage and Displays

PVC foam boards are widely used for signage and window display panels due to their lightweight nature and vibrant colors, providing an eye-catching solution for advertising and marketing.

(2)Furniture Manufacturing

In furniture production, PVC foam boards serve as versatile materials for cabinetry and shelving, offering durability and resistance to moisture, making them ideal for both residential and commercial settings.

(3)Construction and Formwork

PVC foam boards are increasingly used as plastic formwork for concrete, providing a lightweight, reusable, and waterproof solution that simplifies construction processes and enhances efficiency.

Screen

Strorage rack

Sign

Green Plants

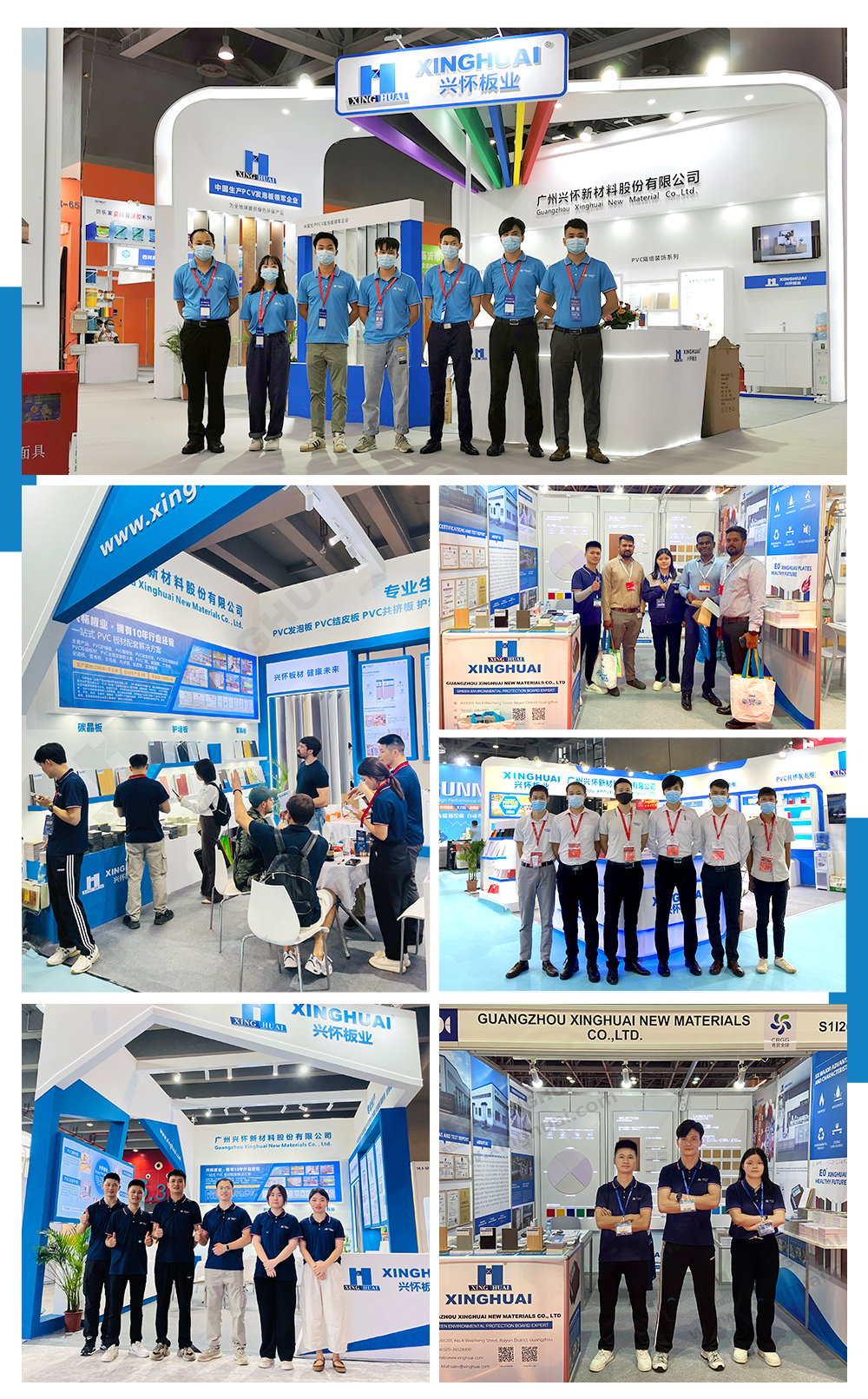

Our exhibition

(1)Networking Opportunities

Trade shows provide valuable opportunities to connect with industry professionals, suppliers, and potential clients, fostering relationships that can lead to new partnerships in areas like solid PVC boards and EVA foam products.

(2)Market Insights

Attending these events allows participants to stay updated on the latest trends and innovations, particularly in materials such as plastic formwork for concrete, helping businesses adapt to market demands.

(3)Product Showcasing

Exhibiting products at trade shows allows companies to showcase their offerings, such as PVC foam boards and EVA sheets, directly to a targeted audience, increasing brand visibility and attracting new customers.